Why Should Infrared Inspection be Your First Choice?

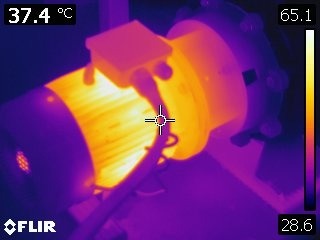

Thermography for a mechanical system, or an infrared survey, provides the entire health status of the scheme. It will provide the condition of boiler jackets, piping, or refractory lining. An infrared study of a motor bearing, coupling or other rotating equipment will include information on its operating condition and locates any overheating parts.

Thermography inspection is also conducted on piping insulation, ductwork, and steam traps to identify leakage or any insulation problem. Thermography inspection can also be used for storage tanks, walk-in freezer and process piping.

Performing Thermography in your facility will add a lot to their predictive maintenance policies as it is going spot instantly all defects and anomalies. Also, a regularly scheduled thermography inspection will help in prediction and optimisation of your future maintenance program. Most importantly, a thermography inspection will predict the estimated maintenance budget.

Thermography Benefits :

✔ Pin-Point Instantly your faulty parts

✔ Down Time Reduction

✔ Prevent Costly and catastrophic system failure

✔ Establish your Repair Priorities based on our report classification

✔ Improve Your Preventive Maintenance Quality and Results

✔ Test Under Load without any planned shutdown

✔ Real-Time Inspections

A Non Destructive Test?

Thermography inspection in a Non-Destructive Test or non-contact testing, where there is no need to schedule any planned shutdown. It is testing your equipment, under standard loads and any of the operating conditions. The Most intelligent benefits of thermography test are to have the testing in real time that will drastically help you to track your problems even after when they stop since it is following their thermal pattern.

What Should be Inspected?

✔ Motors

✔ Boilers

✔ Storage freezers

✔ Piping Insulation

✔ Ducts

✔ Steam Traps

✔ Refractory Lining

✔ Boiler Jackets

Our Digital Thermal Power report is one of an additional differentiator, where we can deliver the report in several ways. The standard traditional paper, or a soft copy and specifically our innovative mobile application that can empower your team and minimize they are follow-up time. It was proven to save 40% of the maintenance team time annually, especially when it comes to thermography inspection. Thanks for our team, who have worked day and night to make that happening.

Thanks for your interest in connecting with your reliable thermal assistance, we welcome your feedback and time. Please contact us directly.